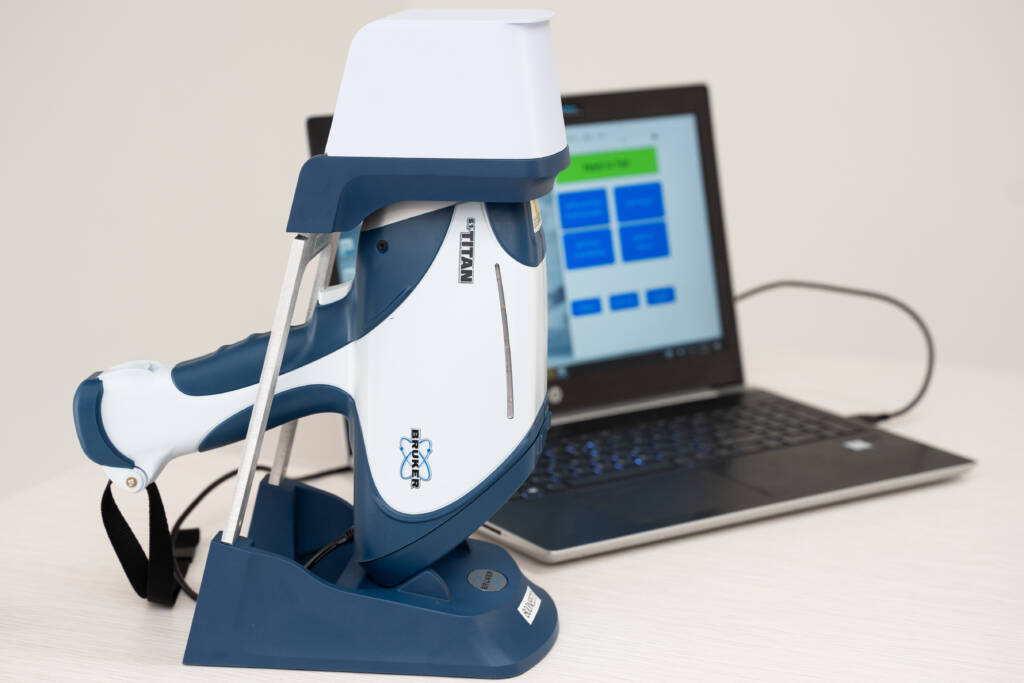

Bruker S1 TITAN XRF

From $170.00 - $535.00 Unit Price

S1 TITAN portable XRF

Day based pricing : Bruker S1 TITAN 800

1 - 2 days :

$535.00 / Day

3 - 6 days :

$415.00 / Day

7 - 13 days :

$335.00 / Day

14 - 29 days :

$310.00 / Day

30 - 89 days :

$280.00 / Day

90 - 179 days :

$230.00 / Day

180 - 360 days :

$215.00 / Day

361 - 366 days :

$170.00 / Day

Description

Additional information

| Weight | 10 kg |

|---|---|

| Dimensions | 54 × 41 × 21 cm |