A Bright Future Ahead

Portable Spectral Services Announces Exciting Management Transition

When getting something constructed or fabricated as a consumer, how do you know that the materials being used are what they say they are and that you are receiving the value you paid for?

Figure 1: Distinguishing between (a) 304 SS & (b) 316 SS can be difficult for the untrained eye, a pXRF analyser can enable you to distinguish them by their elemental composition

(image references below)

In the real world, unethical manufacturers are well known for limiting the content of expensive elements close to the minimum requirement. What happens when the concentration is below the minimum? The sample looks the same to the untrained eye and the consumer ends up with a product that is not within the correct range for that type of material and therefore is not within the acceptable fabrication or manufactured standards. It may be years before anyone realizes the material is not satisfactory, resulting in costly remanufacture and refit, sometimes with potentially disastrous safety and or environment consequences and litigation

This practice is not strictly true for all companies and enterprises responsible for manufacturing and/or fabrication, many operations in practice actively do have independent testing completed before they purchase the manufactured materials. Testing can be done using one or a number of methods. Metallurgical lab analysis and commonly portable hand-held XRF analysers (pXRF) are methods used to confirm if the material being purchased is within the requirement limits. However, the cost of these independent methods is beyond what some companies can justify to be price competitive and instead they use the compliance testing completed in another country by another agency on a much larger batch of material.

Within a single batch, there is the potential for chemical heterogeneity, and so the specific samples from within a large batch that are received by a company may not reflect the composition that is stated on the compliance test provided by the manufacturer. A portable XRF analyzer can remove the guesswork from purchasing steel, alloys and other raw materials used in manufacturing and fabrication, as they provide a reliable chemical composition of the material within seconds.

As a consumer this is not something you should be required to check, but for peace of mind and knowing that the material you have paid for is within the mandatory range for that material class. As a service solution, we have trained technicians who can analyze your samples for you and determine what that are composed of and whether they fit the acceptable standard for that material.

As a company, we recommend the use of an independent testing method for all material received from a manufacturer, to check that it is compliant with the requirements of that material class and that it reflects the quality of the product that you are paying for. Portable XRF analysers are a great tool for this, with grade libraries for alloys and precious metals and the ability to quantify elements from magnesium to uranium.

Contact Portable Spectral Services to find out more information about how portable XRF analysers could be used for compliance testing at your company.

Image references:

Image A sourced from “Stainless Steel Hex Head Bolt, Grade: Ss 304”, Indiamart, 2019, https://www.indiamart.com/proddetail/hex-head-bolt-20647625148.html

Image B sourced from “3/8-16 X 1-inch HWH Drain Bolt, 316 Stainless Steel, 1,” Best Materials, 2019, https://www.bestmaterials.com/detail.aspx?ID=22950.

Portable Spectral Services Announces Exciting Management Transition

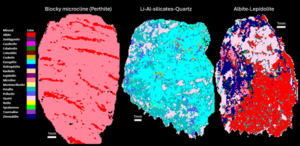

Our tool introduces uXRF (micro-X-ray fluorescence) scanning technology to RC chip analysis, enabling rapid, non-destructive, and quantitative analysis of major, minor, and trace mineral phases.

Automated micro-X-ray fluorescence (micro XRF) technology emerges as a powerful tool to rapidly and accurately capture the mineralogy of rock chip, RC and AC samples.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.